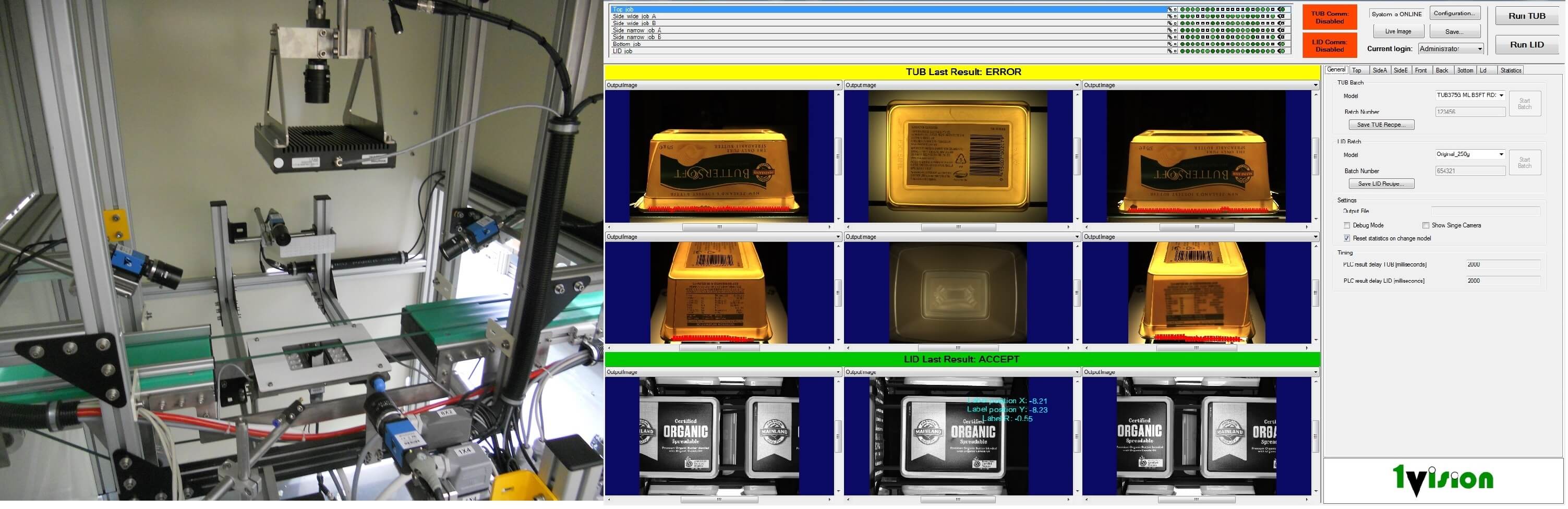

Plastic container visual inspection system

The AOI systems are integrated into In-Mold Labeling Systems (IML)

Margarine Tub and Lid visual inspection

Six sides inspection of tubs, including a bottom inspection.

On-the-fly inspection without the need to stop the conveyor.

A separate lid inspection station

The following visual inspections are performed:

- Wrap-around label position

- Base label X and Y position and angle orientation

- Label deformation

- Correct/missing label

- Barcode verification

- Short shots

- Flashes

The user interface allows dynamic processing parameters update and saves/load of different pre-defined parameter sets (recipes) for different product sizes.

The software calculates, displays and saves statistical data of the current production lot (total products, defected products, % of defects etc.).

Speed= 120 parts per minute.